What is the difference between sensor, transducer and transmitter?

To check the difference between sensor, transducer and transmitter, we must first check the meaning of each of them.

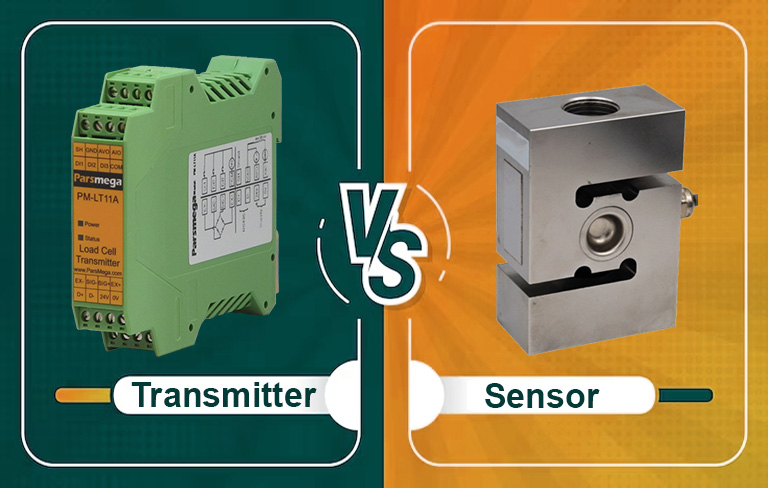

Sensor: A sensor/device that detects or measures a physical property and records, displays, or otherwise responds to it.

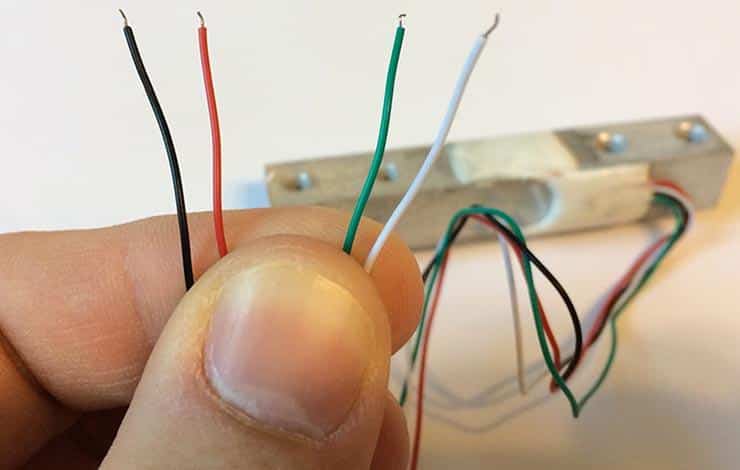

Transducer: It is a converter/device that converts the changes of a physical quantity such as pressure or brightness into an electrical signal and vice versa.

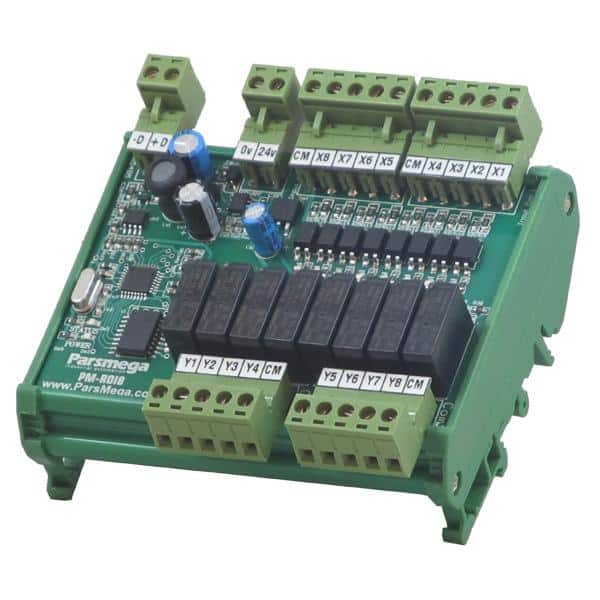

Transmitter: a transmitter/set of equipment used to generate and transmit electromagnetic waves carrying messages or signals, especially radio or television waves.